How Madder lake is made:

| Origin: plant | |

| Madder is a dye that is made into a pigmented by "laking" it - binding it to a white powder.

|

|

| Natural variety of pigment | Roots of the madder plant are dried, crushed, hulled, boiled in weak acid to dissolve the dye, and fermented to hydrolyze anthraquinones from the glycosides. The extracted dye is made into a pigment by dissolving the dye in hot alum (aluminum potassium sulphate; AlK(SO4)2 · 12 H2O) solution, and precipitating pigment with soda or borax. Madder lake production (at Kremer) |

| Artificial variety of pigment | Alizarin lakes are prepared by reaction of alizarine with aluminum hydroxide. |

| 19th century recipe | Carminated Lake from Madder. Boil 1 part of madder in from 12 to 15 pints of water, and continue the ebullition till it be reduced to about 2 lbs. Then strain the decoction through a piece of strong linen cloth, which must be well squeezed; and add to the decoction 4 oz. of alum. The tint will be a beautiful brightred, which the matter will retain if it be mixed with proper clay. In this case, expose the thick liquor which is thus produced on a linen filter, and subject it to one washing, to remove the alum. The lake, when taken from the driers, will retain this bright primitive color given by the alum. |

| In the lab | |

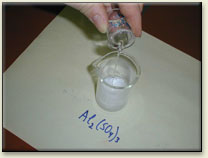

| Materials needed: | Al2(SO4)3, Na2CO3 (anhydrous), Na3PO4, CaCl2, Alizarin and sulfated castor oil |

| Safety (MSDSs): | Castor oil, Sodium phosphate (at Fisher Scientific) |

| Method: | 10 g Al2(SO4)3 is dissolved in 100 ml deionized water at 60°C and treated with a solution of 5 g anhydrous Na2CO3 in 10 ml deionized water. The precipitated aluminum hydroxide is rinsed once with water and placed in a 200 ml beaker. To this hydroxide is added in sequence a solution of 2 g Na3PO4 in 20 ml deionized water, 3 g CaCl2 in 30 ml deionized water and a paste of 20 g alizarin mixed with 4 g of sulfated castor oil (Turkey red oil, a surfactant) and 20 ml of deionized water. The mixture is diluted to 500 ml with deionized water and boiled for 6 hours with replenishment of water. After cooling, the alizarin-alumina-calcium lake is filtered off and dried at the lowest possible temperature. |

Illustration of the process:

making alizarin in the laboratory:

|

|

|

|

|

|

|

|

|

|

|

|

|

The ground pigment:

Pile of ground Madder lake