History of Emerald green:

Schweinfurt green or emerald green was developed in an attempt to improve Scheele's green. This copper aceto-arsenite pigment was first produced commercially by the firm of Wilhelm Sattler at Schweinfurt, Germany in 1814. Justus Von Liebig and Andre Bracconot separately published papers on its method of manufacture. Von Liebig's paper "Sur une couleur verte" was published in 1823 in Annales de chimie XXIII (pp. 412-3). Verdigris (or acetic acid) was dissolved in vinegar and warmed. A watery solution of white arsenic was added to it so that a dirty green solution was formed. To correct the color, fresh vinegar was added to dissolve the solid particles. The solution was then boiled and bright blue-green sediment was obtained. It was then separated from the liquid, washed and dried on low heat and ground in thirty- percent linseed oil. The pigment was considered a good drier.

Schweinfurt green had brilliance unlike any other copper green. Field considered it a more durable pigment than Scheele's green but it had the same tendency to blacken on exposure to sulfur-bearing air. Romanesque murals are known to contain the natural mineral emerald green and have held the color well. The old Masters, who used verdigris and copper greens due to a lack of more durable options, isolated the pigments in between coats of varnish that helped to alleviate changes. Schweinfurt green was also made more stable in a varnish medium. It could not be mixed with sulfur-containing colors, such as cadmium yellow, vermilion or ultramarine blue because they acted chemically on it to produce a deep brown color. Field considered its use to be limited as it was not a green that occurred in nature. The arsenic content made it extremely poisonous and it was blamed for deaths when employed as a wallpaper color.

When was Emerald green used?

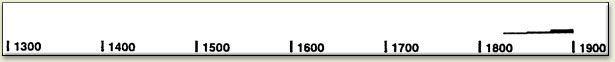

| Discovery | Used until |

|---|---|

| 1814 | 1900s |

Use of Emerald green among paintings in the SchackGallery, Munich:

Source: Kühn

(intro) - Cobalt green - Copper resinate - Emerald green - Green earth - Malachite - Verdigris - Viridian